Exhaust Components and Their Role in System Efficiency

Exhaust Components form the backbone of a vehicle’s exhaust system, working together to control emissions, reduce noise, and maintain optimal engine performance. Each component has a defined role, and failure in one part can disrupt the entire system’s balance. Modern exhaust assemblies are engineered with precision to handle extreme heat, pressure, and chemical reactions. Understanding individual exhaust components helps vehicle owners recognize problems early, maintain efficiency, and avoid unnecessary mechanical stress that can affect long-term reliability.

Exhaust Manifold and Gas Collection Process

The exhaust manifold is the first point where combustion gases exit the engine. It collects gases from each cylinder and directs them into a single flow path. Because it operates under intense heat, the manifold is often made from cast iron or stainless steel. Cracks or leaks in this component can reduce engine efficiency and increase noise levels. A compromised manifold also affects downstream exhaust components, making early detection essential for maintaining overall system integrity.

Exhaust Pipes and Flow Management

Exhaust pipes connect different sections of the system and guide gases toward the rear of the vehicle. Their diameter and shape directly influence gas velocity and back pressure. Poorly designed or damaged pipes can restrict flow, leading to power loss and higher fuel consumption. Corrosion is a common issue, especially in regions with moisture or road salt exposure. Maintaining pipe integrity ensures smooth gas flow and protects connected exhaust components from premature failure.

Catalytic Converter and Emission Control

The catalytic converter is one of the most critical exhaust components for environmental compliance. It uses chemical reactions to convert harmful gases into less toxic substances before release. Internal damage or clogging can severely restrict exhaust flow, affecting engine performance. A failing catalytic converter may trigger warning lights and cause noticeable power reduction. Proper function of this component is essential for emission standards and overall vehicle health.

Oxygen Sensors and System Feedback

Oxygen sensors monitor the amount of oxygen in exhaust gases and provide real-time feedback to the engine control unit. This data helps adjust the air-fuel mixture for efficient combustion. Faulty sensors can cause poor fuel economy, rough idling, and increased emissions. Although small in size, oxygen sensors have a significant impact on how exhaust components work together to maintain balanced engine operation.

Muffler and Noise Regulation

The muffler is designed to reduce exhaust noise while maintaining adequate airflow. It uses internal chambers and baffles to cancel sound waves. Over time, internal corrosion or physical damage can reduce its effectiveness, leading to louder exhaust tones. A damaged muffler may not directly affect engine power but significantly impacts driving comfort and noise compliance. Keeping this component in good condition supports a quieter and more refined driving experience.

Resonator and Sound Refinement

Resonators work alongside mufflers to fine-tune exhaust sound. They target specific frequencies that cause drone or unpleasant tones. While not present in all vehicles, resonators improve sound quality without restricting flow. Damage or removal can alter exhaust acoustics dramatically. Understanding the role of resonators helps drivers appreciate how exhaust components contribute not only to performance but also to overall driving comfort.

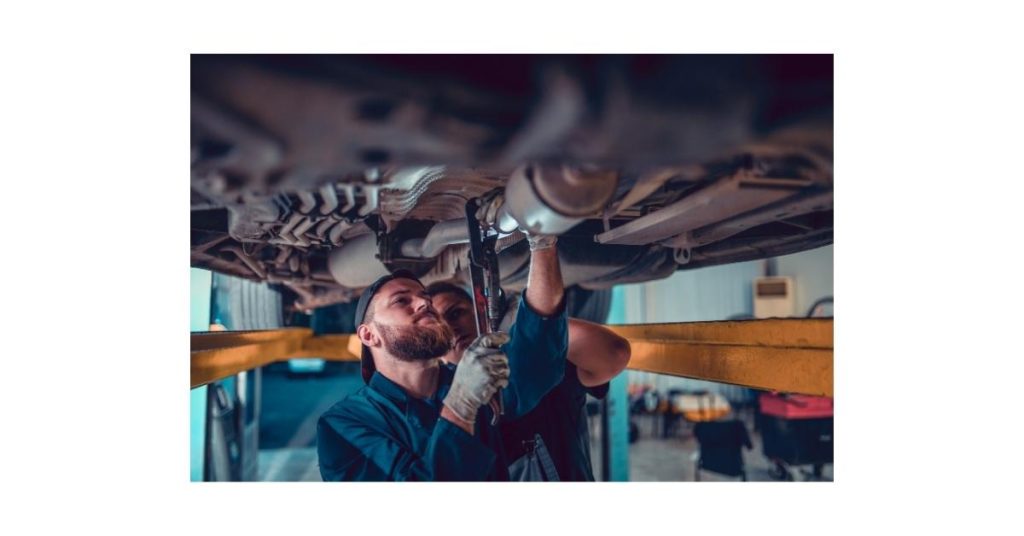

Exhaust Hangers and Mounting Hardware

Exhaust hangers secure the system to the vehicle’s underbody while allowing slight movement to absorb vibrations. Worn or broken hangers can cause rattling noises and misalignment. Misalignment places stress on joints and connections, increasing the risk of leaks. These small but essential parts ensure proper positioning of all exhaust components and prevent unnecessary mechanical strain.

Heat Shields and Thermal Protection

Heat shields protect surrounding components from the extreme temperatures generated by exhaust gases. They are typically made from thin metal or composite materials. Loose or damaged heat shields often produce rattling noises, especially at idle. While they do not affect gas flow, their role in thermal management is critical for protecting wiring, fuel lines, and vehicle flooring from heat damage.

How Exhaust Components Wear Over Time

Exhaust components are constantly exposed to heat cycles, moisture, and corrosive byproducts. Over time, this exposure leads to rust, fatigue, and material degradation. Short trips can accelerate corrosion because moisture does not fully evaporate from the system. Understanding wear patterns helps vehicle owners plan inspections and replacements before failures occur. Preventive maintenance reduces the likelihood of sudden breakdowns and costly repairs.

Importance of Comprehensive System Awareness

A well-maintained exhaust system depends on the condition of each individual component. Learning about Exhaust Components allows drivers to identify abnormal sounds, smells, or performance changes early. Informed awareness leads to faster diagnosis and better maintenance decisions. Reliable technical knowledge from resources like Exhaust Components supports long-term efficiency, emission compliance, and overall vehicle reliability without unnecessary guesswork.